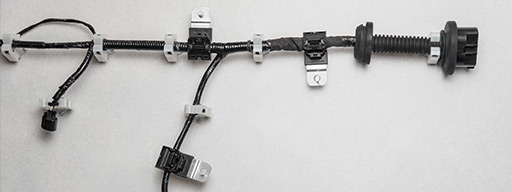

Ratchet P-Clamp by HellermannTyton

Ratchet P-Clamp

Heavy equipment manufacturers constantly look for ways to reduce costs and streamline workflows. But to adopt a new component, it also must meet their needs for versatility, durability and ease of use – without compromising performance.

Ratchet P-Clamp is an innovative wire bundling solution that more than meets those requirements. Featuring an adjustable ratchet clamp mechanism and offered in four sizes as well as four mounting configurations, the Ratchet P-Clamp enables users to reduce parts and inventory costs. And, it cuts the time required for wire harness and cable installation and maintenance.

Engineered for heavy duty applications, it creatively solves wire bundling challenges in OEM, automotive and solar installations.

Automatic Wire and Bundle Alignment

Traditional P-clamps often twist when you torque them down, stressing the bundle. They also can pinch wires when closing, and it’s difficult to adjust cables during installation.

Addressing those issues, Ratchet P-Clamp:

- Allows for pre-installation on the harness and alignment in the final mounting position.

- Adjusts to close at the exact diameter and tension desired.

- Aligns wires to the center as they are secured, reducing pinching.

- Can be closed manually or with an EVO® Series Hand Tool and Tension Tabs.

To provide an extra level of abrasion resistance, we’ve developed Soft Inserts, an accessory that snaps into the clamp and provides enhanced protection when needed.

Elevated Ease of Use

Let’s face it, assembling a metal, two-piece P-clamp and grommet around a cable or bundle, positioning it and then mounting it can be a frustrating task.

Ratchet P-Clamp’s solid body is closed manually, clicking as it closes to ensure it’s secure. Using an EVO Series Hand Tool and an optional Tension Tab can apply an exact tension if desired. Need to open the clamp? No need to remove it – simply insert a small, flat-head screwdriver between the ratchet rails.

Since it’s easy to open and close the clamp, wiring can be adjusted whether it’s in a cramped engine compartment, on a production line robot or between panels in a solar photovoltaic system.

Versatility and Inventory Reduction

Inventory reduction is key to lower operational expenses. With so many different cable sizes, fastening requirements and engineering specifications for P-clamps, most manufacturers must keep an extensive inventory on hand.

We followed customers on the job site and learned installers often need to route bundles side-by-side, must improvise to secure electrical runs as a final assembly step or find a way to work around mounting challenges using washers or other tricks. Sound familiar? To turn challenges into versatility, we:

- Made each clamp size adjustable to accommodate a range of cable sizes from 0.24" (6.2mm) to 2" (51mm) with just four parts!

- Created three lengths of mounting plates and 180°, 15°, 30°, 90° angle orientations.

- Designed Ratchet P-Clamps to be stackable for parallel cable runs and offset applications.

- Added a saddle to the top to give installers another point of attachment

With Ratchet P-Clamp, users can turn “work arounds” into new “best practices.”

Durability Suited for Heavy Duty Application

Ratchet P-Clamp is manufactured from impact modified, heat- and UV-stabilized PA66. There’s no coating to wear away over time, and the patented living hinge is extremely robust. The mounting plate is available in zinc-plated steel for standard applications or stainless steel for extreme corrosion resistance.

That makes it rugged enough for the shock and vibration of heavy duty applications and capable of standing up to extreme temperatures, chemicals, salt spray and constant UV light exposure.

Disruptive Innovation

Ratchet P-Clamp was inspired by customer demand for a lightweight, versatile, lower-cost alternative to old-fashioned, cumbersome P-clamps. Disruptive innovation is rare in any industry. HellermannTyton’s Ratchet P-Clamp, the first member of the Ratchet Clamp family, just might represent disruptive innovation for heavy duty applications.